|

Shot have a slowdown in construction of high-speed filling die casting machine

Ube patented UNI-FF function to prevent the slowdown resulting from the standard flash device。

Improve the ability of P-ACC, injection speed to5m/s。

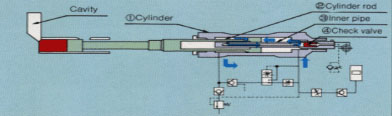

UNI-FFInjection System

High speed:

Deceleration: Fill the end of the mechanical brake to prevent the production of flash

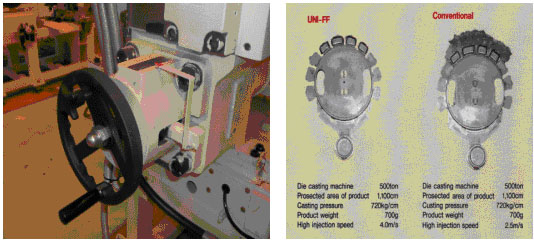

UNI-FFDevice and effect

UNI-FFLocation set deceleration UNI-FFEffect

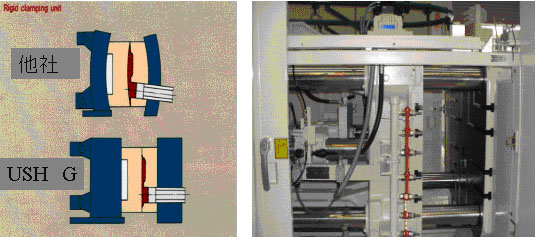

Mold clamping design adequate

Improved operational management, and easy to use

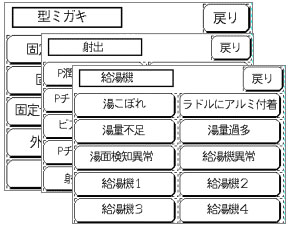

1.PD images used to improve the operational performance

2. In PD frame equipped with a monitoring function. To production management, maintenance and management simplicity. (Screen: production time, IO said the fault alarm display)。

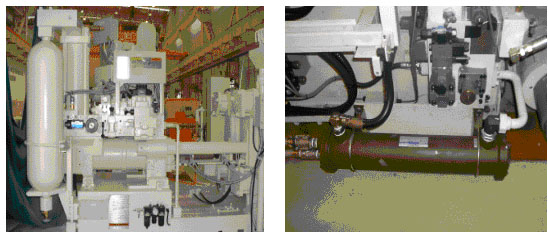

Increase in operating capacity20%

P-ACCThe capacity increase by 20%, and nitrogen bottles connected directly, hydraulic oil cooling capacity increase20%。

Enhance the external environment changes, improved maintainability。

No capacity loss, increased speed。

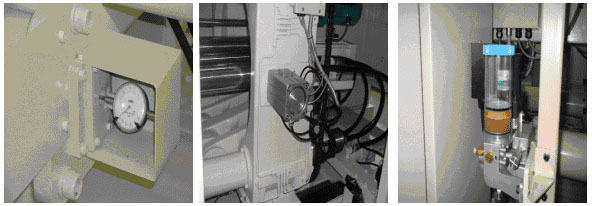

Standard equipment

Dial load table Safety hook Toggle lubrication device

Automation

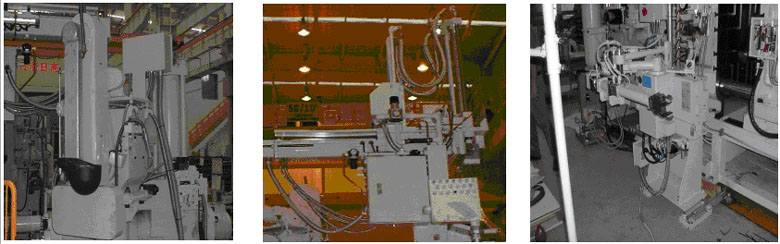

Automatically loaded to the soup Automatic spray device Remove the device automatically

1.Ube system provides automated installation

NCL-type device to the soup

USP-type spray device

Remove the device type ULE

2.Other

Robot spray device

Vacuum devices can provide

| |

Project |

Unit |

UB140Sh |

UB250Dh |

UB350Sh |

| Clamping unit |

Clamping force |

kn(ton) |

1372(140) |

2450(250) |

3430(350) |

| Template Size |

mm |

680×680 |

860×860 |

1028×988 |

| Rod spacing |

mm |

440×440 |

540×540 |

667×667 |

| Rod diameter |

mm |

80 |

110 |

125 |

| Clamping stroke |

mm |

315 |

360 |

420 |

| Template thickness |

mm |

250~500 |

300~600 |

300~700 |

| Mold thickness adjustment speed |

mm/min |

76 |

76 |

76 |

| Ejector unit |

Top output |

kn(ton) |

73.5(7.5) |

122.5(12.5) |

186.2(19) |

| Ejector stroke |

mm |

75 |

80 |

90 |

| Punch |

Punch valves (dynamic mode) |

PIECE |

2 |

2 |

2 |

| Interface Dimensions |

Rc |

3/8 |

3/4 |

3/4 |

| Number of interfaces |

set |

2 |

2 |

2 |

| Pressure |

Mpa |

13.7 |

13.7 |

13.7 |

| Shot unit |

Shot force |

kn(ton) |

153.9(15.7) |

264.6(27) |

333.2(34) |

| Shot travel |

mm |

305 |

415 |

480 |

| Punch capacity conflict |

mm |

120 |

150 |

165 |

| Deceleration adjust position |

mm |

(-10~-90) |

(-10~-115) |

(-10~-130) |

| Cast into the position of |

mm |

(-100) |

(-125) |

(-125) |

| Injection speed (the maximum) |

mm/sec |

5 |

5 |

5 |

| Punch diameter (standard) |

mm |

50 |

60 |

70 |

| Punch diameter (maximum - minimum) |

mm |

45/50/55 |

50/60/70 |

60/70/80 |

| Pump |

Pump(High pressure) |

set |

47.5L/min×13.7Mpa |

67.2L/min×13.7Mpa |

95.2L/min×13.7Mpa |

| Pump (low pressure) |

set |

83L/min×6.9Mpa |

109.9L/min×6.9Mpa |

141.6L/min×6.9Mpa |

| Power Unit |

Pump motor |

set |

15kw, 6P,380V,50Hz |

22kw, 6P,380V,50Hz |

22kw, 6P,380V,50Hz |

| ld thickness adjustment motor |

set |

0.75kw, 4P,200V,50Hz |

15kw, 4P,200V,50Hz |

15kw, 4P,200V,50Hz |

| Machine size |

Long×High×Wide |

mm |

5260×1510×2000 |

5990×1970×2120 |

6680×2020×2410 |

| Machine center heightDegree |

mm |

1040 |

1150 |

1194 |

| Weight |

ton |

5 |

10 |

12 |

| Other |

Tank |

L |

345 |

460 |

510 |

| Oil cooler water supply requirements |

L/min |

40 |

55 |

55 |

| Compressed air |

MPa |

0.49 |

0.49 |

0.49 |

|