|

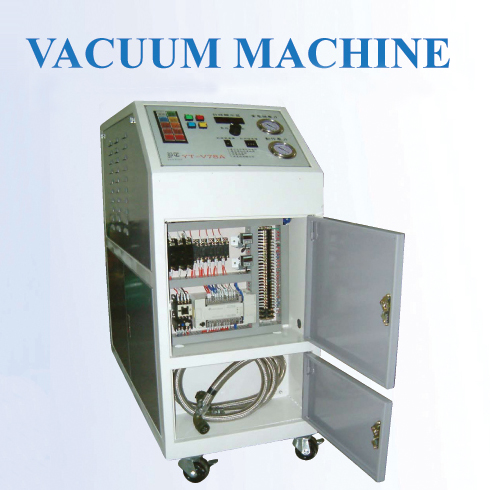

Die-casting machines and vacuum machine, connect the signal line and power line, using the Japanese import of explosion-proof hose with metal quick connectors, machine when not in use can be removed, placed in the machine under the machine admitted box to facilitate movement

Imported German BUSCH

Vacuum Pump

FEATURES

1. Eliminate the pores on the surface of casting parts to

improve the surface fineness.

2. Improve the density of casting parts to make the

component structure more rigid.

3. Solve the bubbling problem in the electro-plating

process.

4. Solve the peeling phenomenon in grinding.

5. Solve the material shortage problem in blind holes.

6. Extend mold life.

7. Improve production efficiency and generate more

profit.

1. Integrated operation panel: gathering all functions in one place for easy operation.

2. Clustered indicators: Obtaining current machine status with a glance.

3. Dip-type PLC Timer function: time setting for accurate casting condition.

4. Large LED timer display for monitoring all single and continuous actions as well as the motor running time.

5. Automatic counting of motor running time and issue notice for oil replacement.

6. Vacuum and blowing in one single piping loop; the vacuum action will remain on standby before extruding to

reduce unnecessary air in tube to be sucked out and speeding up vacuuming in cavities.

7. The signal line of the power supply is protected by a single tube with quick connector which can be removed

and stored in the attached storage case if necessary, saving space.

8. Equipped with electronic positive/negative pressure detector.

9. Uses a ball valve for speedy, clog-free suction.

| Specification/model |

YT-V76B |

YT-V100S |

YT-V152X |

| Suitable die-casting machine |

Cold、hot type |

| Suitable product |

Zinc, aluminum, copper and magnesium alloy |

| Motor size |

3HP |

4HP |

3HP×2 |

| Pump rotational speed |

1750RPM |

1750RPM |

1750RPM |

| Max. noise |

70dBA |

72dBA |

85dBA |

| Pumping speed |

76m3³/hr |

120m3³/hr |

152m³3/hr |

| Voltage |

AC220/380V |

| Guaranteed end vacuum |

750mmHg |

| Corresponding method |

One-to-one single-circuit |

ne-to-one dual-circuit |

Central system |

| Pressurized tank capacity |

84L |

150L |

500L |

|