|

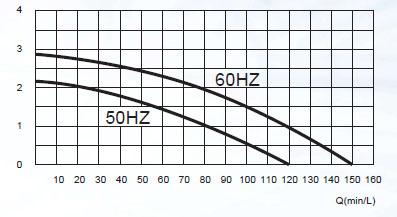

Pump performance curves for YT-T-2520

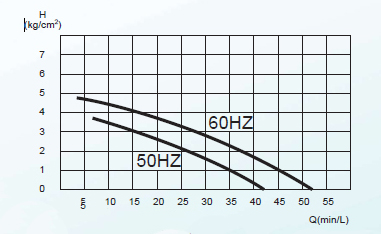

Pump performance curves for YT-T-3015

FEATURES

1. The control box and the machine are separated to increase

thermal insulation and extend the parts¡¯ life span.

2. The internal oil circulation pipes will automatically fill up the oil

and eliminate entrapped air upon startup of the machine, which

prevents dry running which can cause heater and motor failure.

3. The "YAMATAKE" P.I.D microcomputer automatic algorithm

imported from Japan is used for temperature control to ensure

accuracy and stability, and keep the exit temperature difference

within ¡¾0.5¡ÆC.

4. FUJI, L.G, and O.D.E imported parts are used for all heater

components.

5. SPECK, CIRO and TECO oil pumps are used for max heating/

cooling speed, saving electricity cost.

A. Temperature deviation and warning indicator:

When the exit temperature differs from the setting by more than

2¡ÆC~4¡ÆC (deviation value can be set), the buzzer and indicator

will be activated.

B. Force cooling:

Press this button before ceasing operation; the heated circulation

oil will be forced to cool down automatically.

C. Automatic oil discharge

When the heated circulation oil cools down to room temperature,

press this button to discharge all oil in the pipes between the

mold temperature controller and mold into the oil tank by air.

Safety protection and indicator system

1. Phase protection of power supply

2. Leak-proof protection switch

3. Pump reversal protection and indicator

4. Pump overload protection and indicator

5. Over-heat protection and indicator

6. Hot circulation oil BY-PASS pressure releasing loop

7. Temperature abnormality alarm and indicator (FS series)

8. Error alarm and buzzer

9. Oil shortage protection and indicator

Optional parts

2. Thermocouple for connecting to external device

3. Thermometer display for oil return temperature

4. Voltage abnormality protection switch

5. Teflon tube

| Specification/model |

YT-T2010F

YT-T2010FS |

YT-T2010FD

YT-T2010FSD |

YT-T2020F

YT-T2020FS |

YT-T2020FD

YT-T2020FSD |

YT-T2520F

YT-T2520FS |

YT-T3015F

YT-T3015FS |

| Power supply (V/HZ/3¨ª¨ª) |

AC220~440 50/60 |

| Max. Temp. (¡É) |

200 |

250 |

300 |

| Min. Temp. (¡É) |

60 |

80 |

| Medium for heat |

Oil |

| Heating energy(KW) |

9 |

9×2 |

9 |

9×2 |

9 |

| Cooling energy(Kcal/hr) |

3000 |

3000×2 |

3000 |

3000×2 |

6000 |

| Cooling method |

Indirect cooling |

| Accuracy of Temp. control (¡É) |

±0.5 |

| Oil tank capacity(L) |

10 |

15 |

10 |

15 |

10 |

| Pump hosepower (KW) |

0.75 |

0.75×2 |

1.5 |

1.5×2 |

1.5 |

1.1 |

| Pump Max. flow (L/min) |

50 |

45 |

110 |

450 |

50 |

| 60 |

55 |

110 |

500 |

60 |

| Pump Max. pressure (kg/c§³) |

50 |

3.2 |

5.0 |

2.2 |

5.5 |

| 60 |

4.0 |

5.0 |

2.3 |

6.5 |

| Max. Power(KW) |

9.75 |

19 |

10.5 |

21 |

10.5 |

10.1 |

| Pressure of external cooling water (kg) |

1.0 |

| Size of cooling water tube(inch) |

1/2 |

| Size of hot water tube (inch) |

4×4, 3/8 OR 1×1, 3/4 |

| Size of mold Temp. controller L¡¿W¡¿H(mm) |

730×300×750 |

890×400×850 |

730×300×750 |

890×400×850 |

730×300×750 |

| Weight of mold Temp. controller (kg) |

73 |

120 |

75 |

130 |

80 |

|